xuxin shoes factory

Two Advanced Shoe Factories

Two Advanced Shoe Manufacturing Factories for Efficient Production

Dual Factories to Meet Diverse Production Needs

Xuxin Shoes operates two advanced shoe manufacturing factories, designed with strategic layouts and efficient management to ensure stable and flexible production capabilities, providing reliable capacity for customers worldwide.

xuxin factory 1

High-Efficiency Mass Production Base

Focus: Specialized in large-scale bulk orders.

Strengths: Equipped with modern assembly lines to ensure high productivity and quick turnaround for urgent orders.

Key Products: Primarily produces safety shoes, sports shoes, and other high-demand categories.

xuxin factory 2

Flexible Customization and R&D Center

Focus: Specialized in small-batch customization and new product development.

Strengths: Offers flexible production capabilities, supporting diverse designs and unique customer requirements.

Key Features: Equipped with advanced testing facilities and strict quality control processes to guarantee superior product quality.

Combined Advantages of the Two Factories

Two Advanced Shoe Manufacturing Factories for Efficient Production

Ample Production Capacity

The two factories work collaboratively to meet large-scale and diverse production demands effortlessly.

Fast Delivery

Optimized workflows ensure smooth and efficient processes from production to delivery.

Personalized Services

Whether for standard production or custom designs, our factories are equipped to respond promptly to your needs.

Quality Commitment

Both factories strictly adhere to international standards, ensuring comprehensive quality control and environmentally friendly production practices.

Two Advanced Shoe Manufacturing Lines

Advanced Production Lines Ensuring Quality and Efficiency

Xuxin Shoes is equipped with two complete production lines: the Cold Adhesive Line and the Injection Line. Each line is composed of approximately 20 independent processes, covering every step from raw material handling to finished product packaging. With scientifically designed workflows, we ensure both high efficiency and top-notch quality, meeting diverse customer needs ranging from large-volume orders to customized production.

Cold Cement Line

The cold adhesive process is renowned for its flexibility and adaptability to various shoe types, particularly ideal for producing sports shoes and casual footwear.

1 cement line

2 cutting

3 stitching

4 stitching insole pad

5 putting on protect toe

6 gluing

7 lasting

8 lasting the heel

9 sanding

10 fitting outsole

11 underlining

12 brushing treated water for upper

13 brushing glue for upper

14 brushing glue for outsole

15 sticking the outsole

16 pressing fit

17 nourishing glue

18 pressing fit again

19 putting on the insole

20 quality inspection

21 packing

22 putting into finished product warehouse

Injection Line

The injection process is celebrated for its high efficiency and structural integrity, making it particularly suited for the large-scale production of safety shoes and specialized footwear.

1 cutting

2 stitching

3 stitching insole pad

4 putting on protect toe

5 gluing

6 lasting

7 preheat the molds and equipment

8 inserting lasts

9 sanding the upper

10 clamping molds

11 injecting PU material

12 closing the molds

13 remove lasts

14 trimming

15 lacing

16 placing insoles and shoe trees

17 Inspection

18 packing

Xuxin Testing Laboratory

Multiple tests determine product quality

At Xuxin Shoes, quality is our top priority. To ensure every pair of shoes meets international standards and exceeds customer expectations, we have established a state-of-the-art testing laboratory equipped with advanced testing machines.

At Xuxin Shoes, quality is our top priority. To ensure every pair of shoes meets international standards and exceeds customer expectations, we have established a state-of-the-art testing laboratory equipped with advanced testing machines.

Bending Tester Machine

Simulates repetitive bending conditions to ensure the durability and flexibility of shoe materials.

Tensile Testing Machine

Measures the tensile strength of materials to guarantee that our products withstand heavy use and stress.

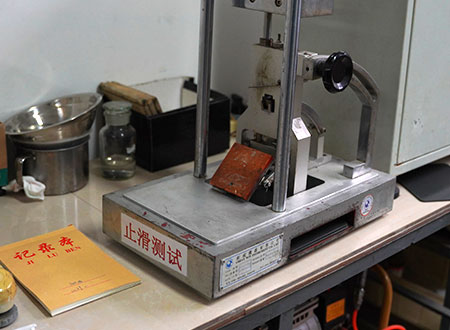

Slip Resistance Tester

Evaluates the slip resistance of shoe soles under various conditions to ensure safety and comfort for end-users.

Yellowing Resistance Tester

Tests materials’ resistance to yellowing under UV light, maintaining their appearance over time.

Abrasion Testing Machine

Assesses wear and tear on shoe materials, ensuring they remain durable and reliable during extended use.